Project Data

Type: Temporary Exhibition – Digital Fabrication

Location: Dessau, Germany

Client: Hochschule Anhalt

Year: 2018

Budget: 20 000 Euro

Project Director: Karim Soliman

Design Team: Maria Quittenbaum, Mahmoud El Naggar, Andrea Ordeveska & Lisa Madeline Petzold

Structure Consultant: Buro Happold Berlin

Digital Fabrication: Form Cut Berlin

Visualization Team: Amro Hamead & Hossam Badr

2D Documentation: Manuel Emad & Mohamed Abdo

3D Documentation: Octavian Catlabuga

Construction Coordinator: Valmir Kastrati

Exhibition Curation: Chidlim Obi, Atari Beredugo, Mohamed Shalaby & Kamal Amgad

Movie Credit: Geoffrey Chew

Project Description:

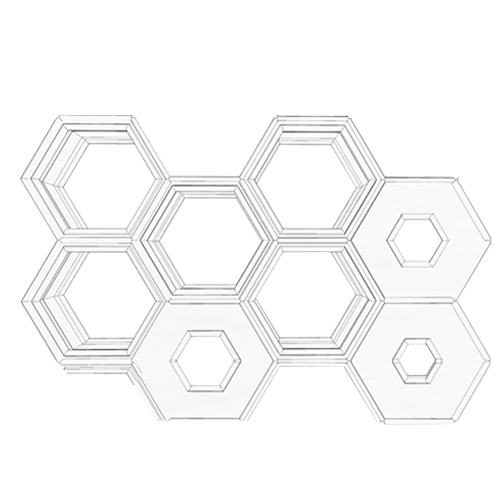

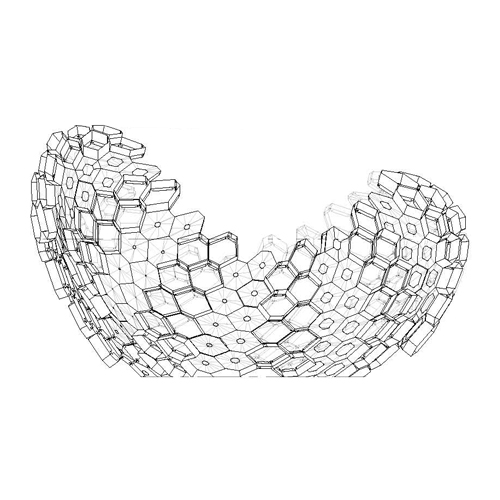

The pavilion’s design intent was to exhibit 12 parametrically designed jewelry pieces, designed by students during the 2017/2018 year as well as host other exhibitions, parties or seminars. The concept was inspired by a Hornet nest considering a biomimicry approach and the main idea was the aspect of layering to create layers of cellulose, which overlapped to build an envelope.

Rendering their expertise, Büro Happolt worked alongside the team to further develop the structure of the Hornet Nest. With concerns regarding the weight of the structure, its durability and thickness of members, alterations were made.

Since the material inside the v-shaped cut can deteriorate with time, a stiffer structure with more durable connections was recommended and in order to maintain the concept, some layers and units of the pavilion were doubled, resulting in more depth and stability. A new plug-in, a plus-minus-connection, was used to build arches which are connected with the old “plug-in-system, using horizontal units. Necessary connections in which allows the Hornet Nest to stand securely in its place.

The timber structure comprised a total of 322 parts to be cut and numbered using CNC (Computer numerical control) machines however, due to unfortunate circumstances the sponsorship obtained was only sufficient to assemble half of the Hornet Nest.

After a prototype was tested, the units were mass produced by a local company and the assembly began in its present outdoor location. Seeing that there was no need for power tools, the process was quite laborious and much man power was required. Nevertheless, the portion built was successfully erected in one day, fabrications from other students were displayed on the designated rectangular cells and the Hornet Nest was ready to fulfill its function.